Spill lighting is simply light that falls outside the area that is intended to be lit. We have already discussed the impacts this can have on our environment in previous editorials but how can we eliminate this spill lighting and ensure we are providing a fit for purpose lighting solution.

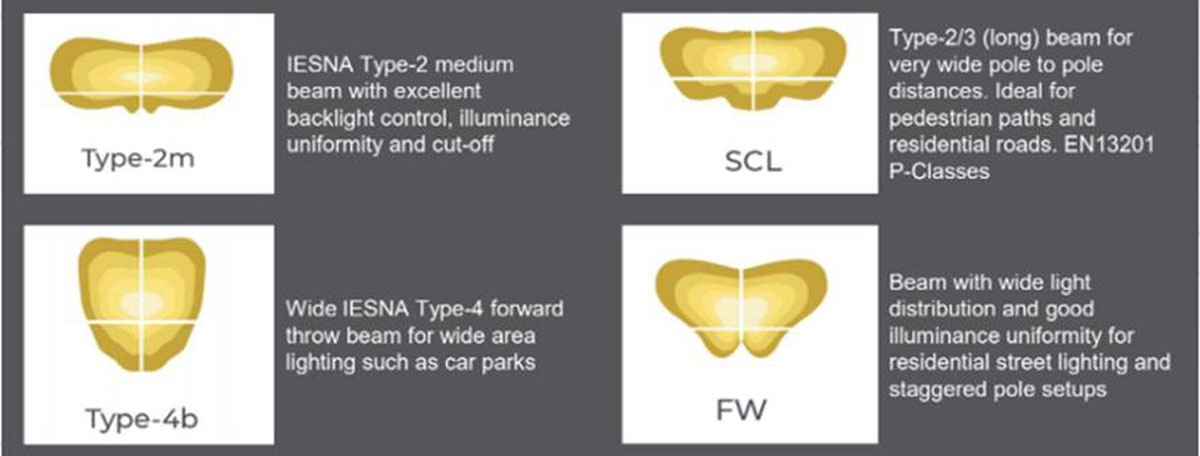

The technological developments over the past few years in lighting have provided us with a number of options to control the distribution of light. A quality LED light fitting should now offer a range of different beam spreads. Using lenses that cover the LEDs, the direction of light can be controlled and directed to only the area it is required. Below are some typical distributions that a quality light fitting should be able to offer.

To ascertain how a light fitting will perform, it is tested by an independent and accredited lighting laboratory. This test will generate a report which is known as an IES file. This file contains data that when used in a lighting calculation software program such as AGI32 or Dialux will show exactly how the light fitting will perform and where the light will be distributed. If a light fitting doesn’t have an IES file, there is no way to be sure how the fitting will perform which is likely to cause a lot of problems with spill lighting and glare. If you are considering using a light fitting without an IES file, tread warily!

Further to using lens technology, light fittings can also be installed with a cut off shield. This would act as a complete block of light and is useful in applications where you require the light to be abruptly stopped. For example, you may be lighting a garden area, and have neighbours next door and need to ensure there is no spill directed into the neighbouring property.

With the ever-improving technology available, lighting designers are also now able to design their own beam spread. Combining interchangeable and rotatable micro lens optics offers the designer complete control, giving them the ability to design a completely bespoke fitting that will perfectly illuminate their project, ensuring light is only where it is needed, with zero spill light.

For further information on any of the above, please don’t hesitate to contact our office who will be happy to assist, and in part 2 we will examine other ways of controlling light fittings.